betaling Type:L/C,T/T,D/P,Paypal

Incoterm:FOB,CIF,FCA,CFR,EXW,CPT,CIP,DEQ,DDP,DDU

Min. orde:100 Kilogram

vervoer:Ocean,Land,Air

Haven:Shanghai,Qingdao,Shenzhen

$1.99-9.9 /Kilogram

Model: HP-100

merk: HP-plaat, HP-lassen

Standaard-: ASTM, DIN, GB, AiSi, bs, JIS

Plaats Van Herkomst: China

Soorten: Getrokken draad

Toepassing: Bouw, VERVAARDIGING

Of Legering: Is legering

Speciaal Staal: Gratis snijdend staal

Tolerantie: ± 1%

Verwerkingsservice: Lassen

Standard Diameter: Φ1.2, Φ1.6, Φ2.8, Φ3.2

Package Standard 1: 15kgs/Reel

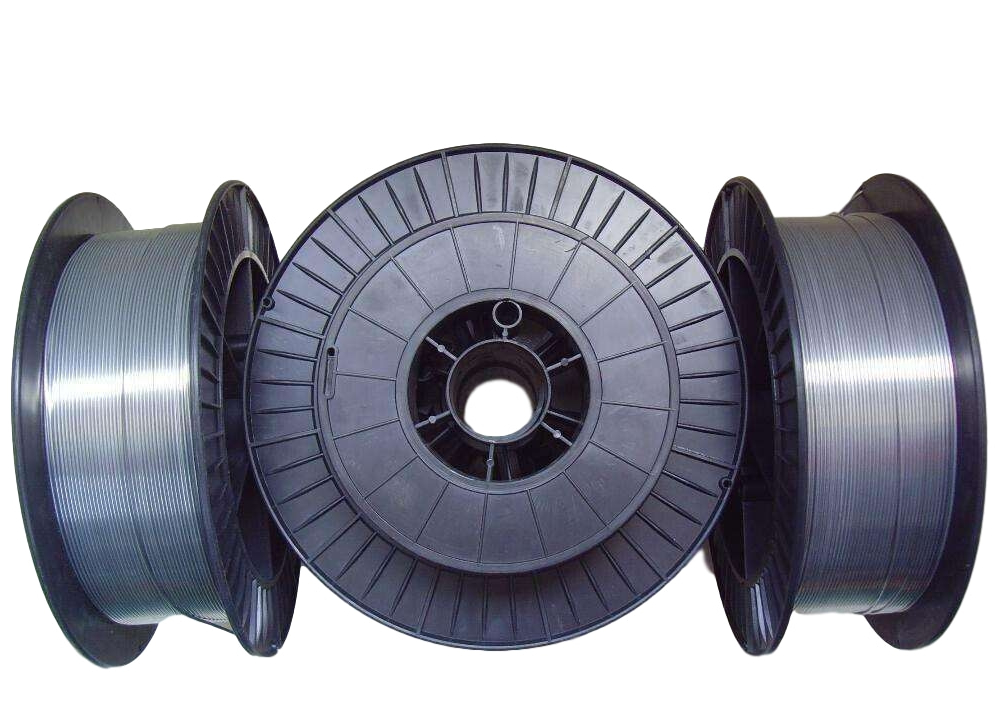

Package Standard 2: 250kgs/Drum

verpakkingen: Stalen frame en stalen riem bevestigd

produktiviteit: 10 tons daily

vervoer: Ocean,Land,Air

Plaats van herkomst: China

Ondersteuning over: 10 tons per day

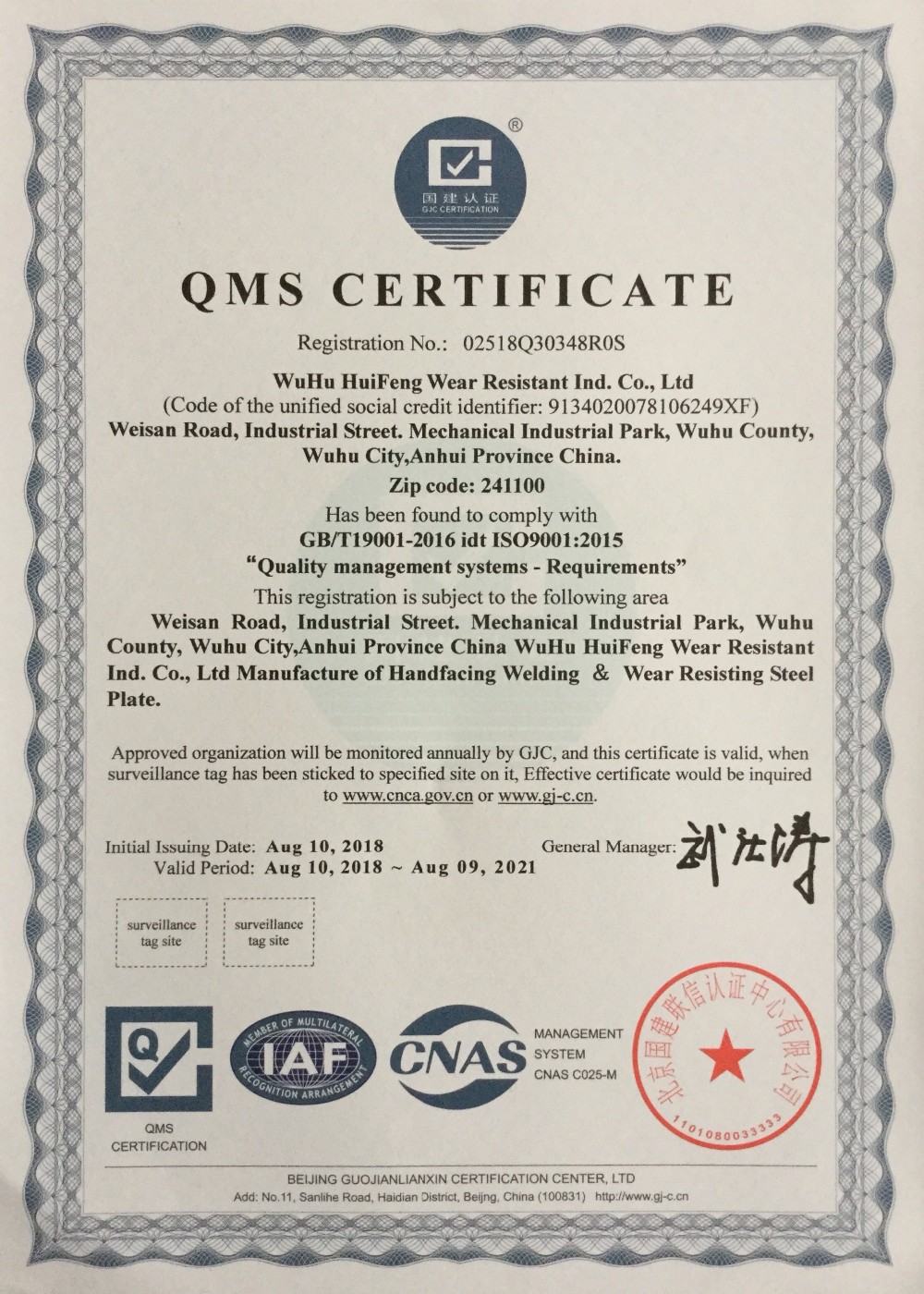

Certificaat: ISO9001: 2015

GS-code: 8311200000

Haven: Shanghai,Qingdao,Shenzhen

betaling Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CIF,FCA,CFR,EXW,CPT,CIP,DEQ,DDP,DDU

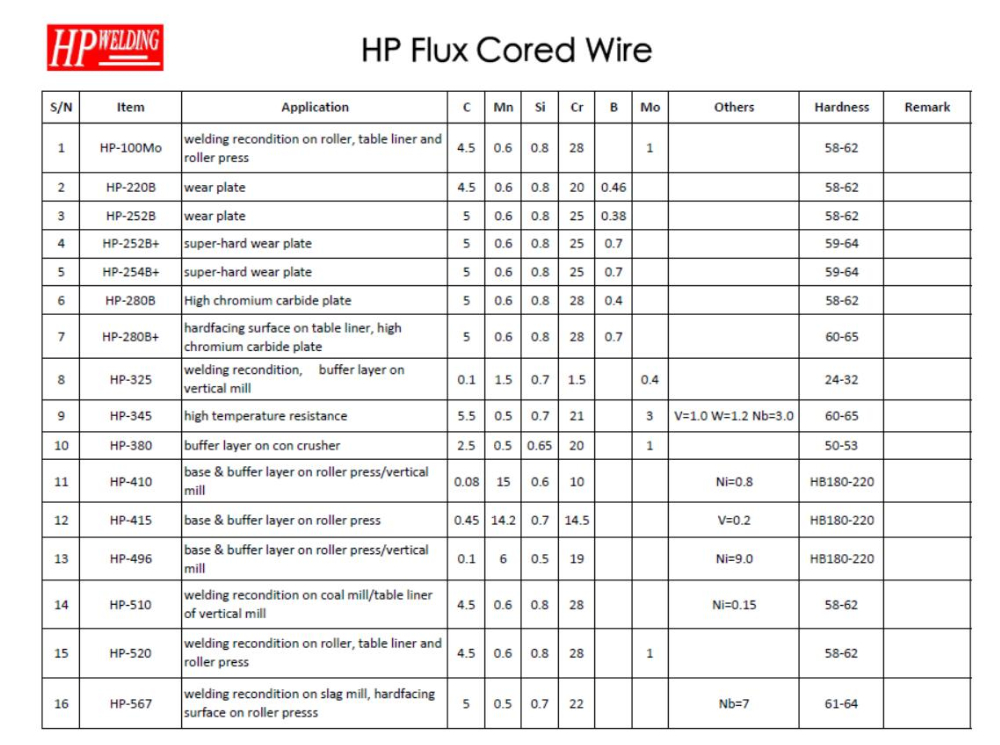

HP Welding manufactures an extensive range of High Chrome Flux Cored Wire and metal cored hardfacing consumables. We offer welding wires for low, medium and high alloy hardfacing, which provide the ultimate protection against various types of wear, including abrasion, erosion, impact, mechanical fatigue, and more.

Equivalent to ESAB Welding Wire, HP FCAW Welding Wire is ideal to produce buffer layer before hardfacing with chromium cast iron. The wire is ideal for the applications like repair work on railway frogs and crossings, hammers, bars, cones and jaws for crushers.

For example, Hard Surface Welding Wire HP100Mo has good ability of a material to increase its surface hardness under the effect of impact or high pressure. In general, this increases wear resistance.

Flux Cored Chromium Welding Wire enables a Cr-Mo-V alloyed deposit for semi automatic and automatic surfacing. It is good for repair of manganese steel buckets and shovels, high tensile tools & dies, clutches, crane wheels, earthmoving undercarriage parts, gear wheels, etc with good resistance to tempering and good crack resistance.

Standard Specifications of HP Wear Plate by HP flux cored wire:

Verpakking en levering van Flux Cored-draden

Verpakking en levering van Flux Cored-draden

Verpakkingswijze: OPT.1_5KG by Reel , OPT.2_ 250KG by Drum

Delivery Time: 20 days after order confirmation

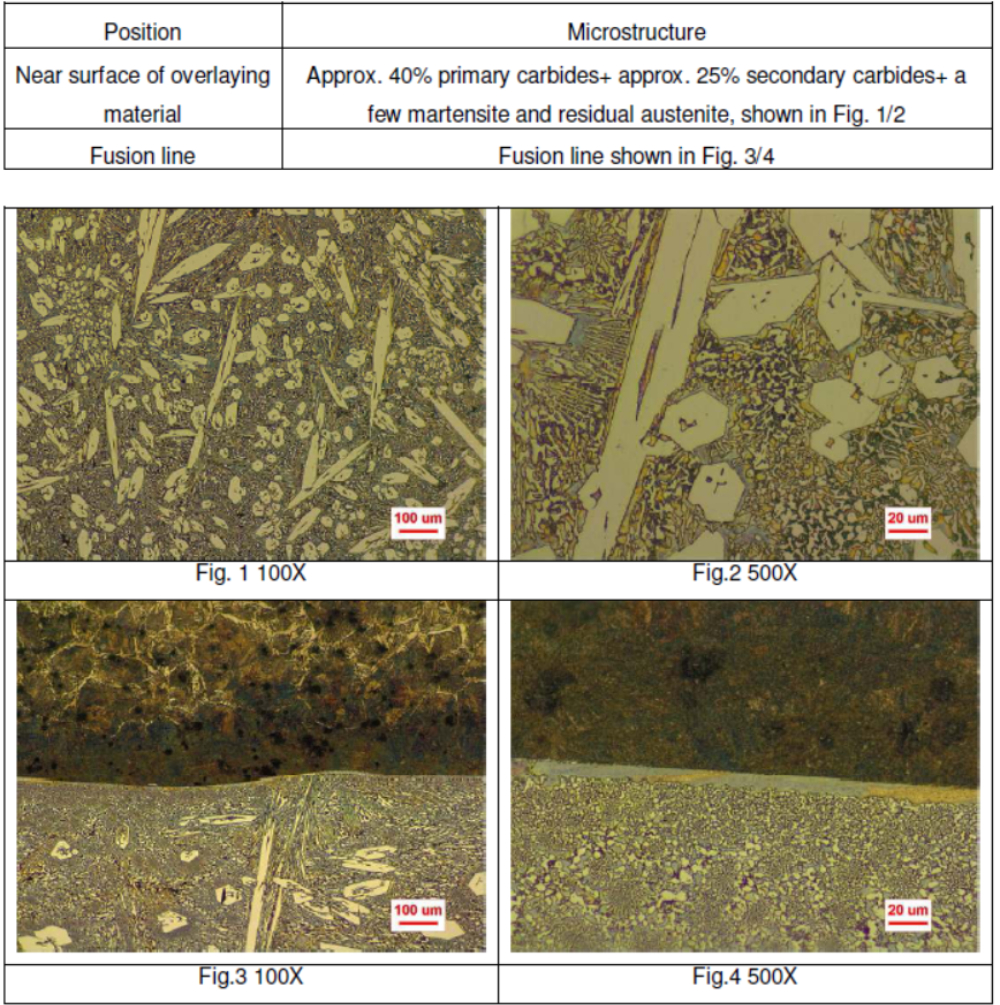

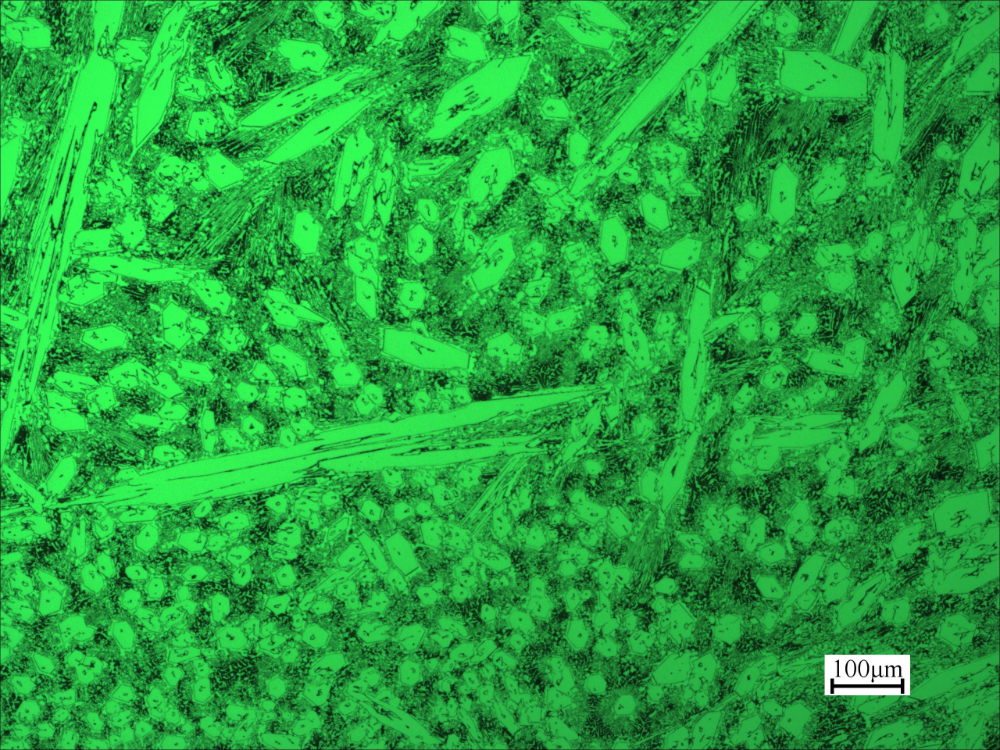

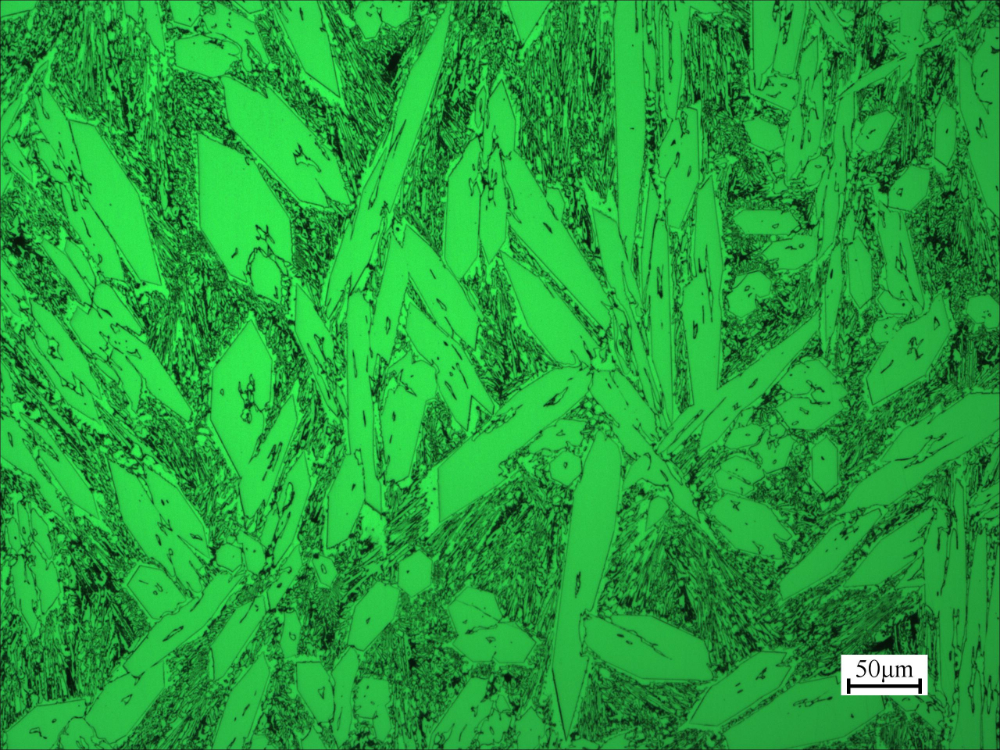

Micro-structuur op lasafzetting

bedrijfsinformatie

HP Wear Resofanat Group werd opgericht in 1994, als de voormalige Taiwan's Upking-Kurimoto Ltd., geleid door president Mr. Zhang Kun-Mou, met behulp van de wereldberoemde Japanse Kurimoto hardfacing lassen gepatenteerde technologie en lasmaterialen geproduceerd door Vautid GmbH. HP Group is de meest ervaren expert geworden die gespecialiseerd is in productie en verkoop van slijtvaste producten.

Test Facilities On Welding Wires

Company ISO Certificates:

FAQ op HP Wear-producten

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Antwoord: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.