betaling Type:L/C,T/T,D/P,Paypal,Others

Incoterm:FOB,CFR,CIF,EXW,FCA,FAS,DAF,DES,CPT,CIP,DEQ,DDP,DDU

Min. orde:50 Kilogram

vervoer:Ocean,Land,Air,Express,Others

Haven:Tianjin,Shanghai,Qingdao

$1.9≥50Kilogram

Model: HP-RL

merk: HP-plaat

Plaats Van Herkomst: China

Verwerkingsservice: Vorming, Snijden

Specified Size: Make To Order

verpakkingen: Stalen frame of houten behuizing

produktiviteit: 500 Ton per year

vervoer: Ocean,Land,Air,Express,Others

Plaats van herkomst: China

Ondersteuning over: 500 tons per year

Certificaat: ISO9001: 2015

GS-code: 4016999090

Haven: Tianjin,Shanghai,Qingdao

betaling Type: L/C,T/T,D/P,Paypal,Others

Incoterm: FOB,CFR,CIF,EXW,FCA,FAS,DAF,DES,CPT,CIP,DEQ,DDP,DDU

Vanwege de goede elasticiteit van de rubberen voering kan deze worden vervormd onder invloed van een stalen kogel, zodat de kracht klein is, voor zachte materialen is de levensduur van de rubberen voeringplaat 2 ~ 3 keer hoger dan die van mangaanstalen voeringplaat, en hoe hoger de hardheid van het materiaal, het voordeel van slijtvaste rubberen voeringen is een grotere slijtvastheid

Stalen voeringplaat kan worden gecorrodeerd door zure slurry, maar slijtvaste rubberen voering is niet gevoelig voor zure of alkalische media zoals waterdamp bij een bepaalde temperatuur, alleen olie en ozon (gegenereerd door krachtige motor) corrosie erop eenvoudig te monteren en demonteren;

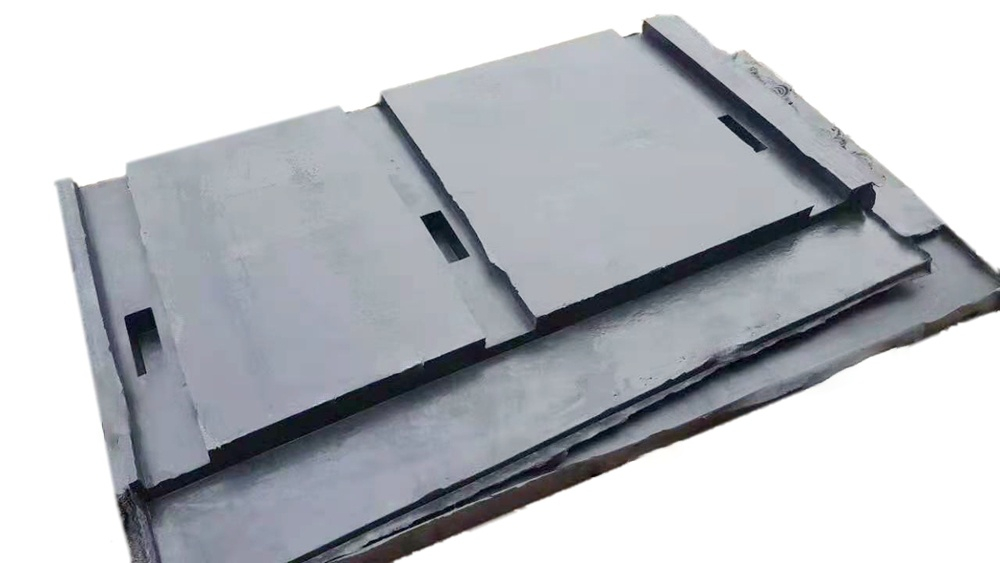

Cement Ball Mill Liner Plate, Ball Mill Reserveonderdelen en Shell Lifter Bar zijn ideale slijtage-oplossing voor Cement Ball Mill

Zeer belangrijke specificaties van rubberproduct :

| Performance Index |

Unit |

Standard |

|

Tensile strength |

Mpa |

17 |

|

Elongation |

% |

420 |

|

Permanent Deformation |

% |

10 |

|

300% Tensile Strength |

Mpa |

11 |

|

Impact Elasticity |

% |

45 |

|

Wear Reduction |

cm³/1.61km |

0.15 |

|

Shore (a) Hardness |

65±5 |

|

|

Aging Coefficient (70℃*48h) |

0.8 |

Ball Mill Liner components:

Our ball mill liners solutions can be fitted with lifter bars, shell plates and head plates. We utilise Hardox wear-resistant steel, attached to the leading edges of the lifter bar array and embedded within shell plates and head plates, ensuring maximum abrasion and impact resistance.

Shell Plates

Shell plate thickness can vary, which helps both in balancing mill capacity as well as extending ball mill liner life. For arduous milling applications, or where drilling patterns produce shell plates that are too wide, thus exposed to high wear, shell plates with Hardox strips can be utilised.

Lifter Bars

Available in a range of profiles and dimensions, lifter bars increase the efficiency of the milling operation by maximising the agitation of the ore. The impact and abrasion resistance of these bars is maximised by Hardox steel along the leadings edges of these components. With a high-quality attachment system, lifter bars are easy to install to the ball mill liner.

Head Plates

We custom-design head plates according to each ball mill to ensure maximum performance and lifespan. Most commonly, our head plates are built from high-quality, specially-formulated rubber. In arduous ball mill applications, Hardox strips can be fitted to the head plates to increase their operational life.

Grate Plates

Grate plates are available in a range of aperture sizes and configurations. Internal frames are designed for different mill loads, and it is possible to use semi-overflow designs in order to control the pulp level in the mill. Different options for extending plate life exist as required by your application, such as built-in lifter bars.

Pulp Lifters

Manufactured with a rubber-lined fabricated steel base, our pulp lifters use high-quality designs that ensure a correct volumetric flow of the pulp. Rubber wear plates designed to be bolted onto the high-wear areas of the ball mill liner improve the performance life of your mill.

Central Cones

These components assist in the controlled discharge of the material, maintaining mill capacity across the operation. Cones are provided in segments, which are then assembled inside the mill. This enables easier handling and manageability.

Trunnion and Bell Mouth Liners

Manufactured with a fabricated steel base that is then rubber lined. Loose steel-reinforced rubber liners are also used in larger trunnions.

Filling and Support Segments

Extend the wear liner to the corners of your ball mill and scrubber, enabling a clean, smooth lining across the ball mill liner.

Key Specifications Of Rubber Product:

Unit

Standard

Tensile strength

Mpa

17

Elongation

%

420

Permanent Deformation

%

10

300% Tensile Strength

Mpa

11

Impact Elasticity

%

45

Wear Reduction

cm³/1.61km

0.15

Shore (a) Hardness

65±5

Aging Coefficient (70℃*48h)

0.8

Packing & Delivery

Packing Way: By Wooden Case, By Steel Belt, By Steel Pallet

Delivery Time: 4 weeks after order confirmation or to discuss

Company Information

We are specialized in designing and manufacturing wear resistant products including anti-abrasion rubber lining, polyurethane lining, wear resistant steel products, ceramic liner, conveyor accessories, etc. Our products are widely used in bulk material handling industries including coal mine, steel plant, power generation, cement plant, metallurgy, chemical and other fields.

HP Wear Solution Products Show Case:

HP Factory Laboratory

Performance Index

V1: Is aanpassing beschikbaar?

A: We ondersteunen aanpassing volgens uw verzoek.

V2: Hoe lang is uw levertijd?

A: 3 ~ 4 weken. We hebben belangrijke grondstoffenvoorraad bij behoefte aan dringende volgorde en de prioriteit wordt gegeven wanneer dat nodig is.

V3: Kunnen we uw fabriek bezoeken?

A: Ja, u bent van harte welkom om ons te bezoeken. Deel ons gewoon uw reisroute indien beschikbaar.

Q4: Wat is de kwaliteitscontrole op producten.

A: Elk product zal strikt worden geïnspecteerd vóór de levering

V5: Zijn de monsters gratis?

A: Ja, gratis monster is beschikbaar of om te bespreken.

V6: Welke informatie is vereist om door te gaan met inkooporder?

A: Het zou ons geweldig ondersteunen als technische tekeningen in detail worden verstrekt.