Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

HP wear-resisting plate, ie, double-metal wear-resistant steel plate, double-metal clad wear-resistant steel plate, is a plate product specially designed for large-area wear conditions, and it is passed through the surface of ordinary mild steel or low alloy steel with good toughness and plasticity. Overlay welding method A board product made by compounding a certain thickness of a wear layer with high hardness and excellent abrasion resistance.

The bimetal composite wear-resistant steel plate is composed of two parts, a low-carbon steel plate and an alloy wear layer, and the anti-wear layer generally occupies 1/3-1/2 of the total thickness. During work, the base body provides comprehensive properties such as strength, toughness, and plasticity that resist external forces. The wear layer provides wear resistance that meets the requirements of the specified working conditions.

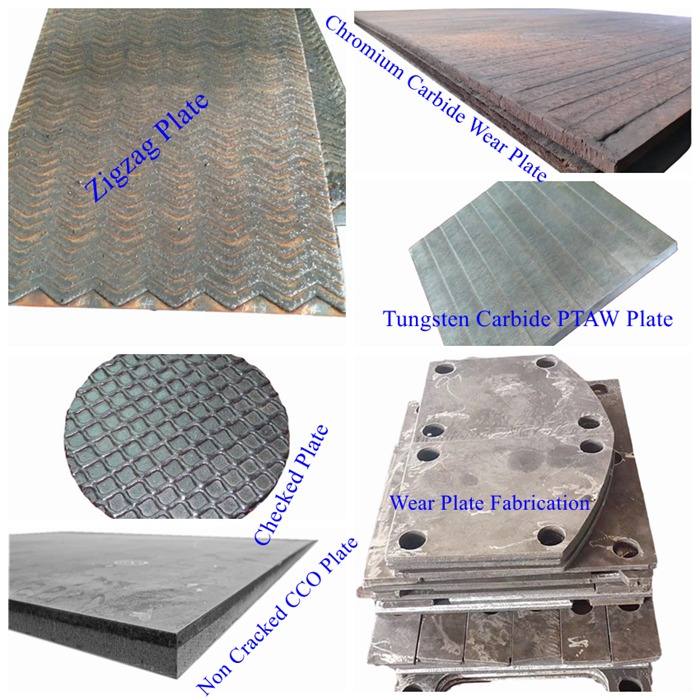

HP Wear Resistant Group is mainly engaged in the development and production of wear plates. The company's main products include CCO Plate, Tungsten Carbide Wear Plate, NM360 wear plate, NM400 wear plate, NM450 wear plate, NM500 wear plate, etc.

Wear-resistant steel alloy wear layer and matrix is metallurgical bonding. Through special equipment and automatic welding process, the high-hardness self-protecting alloy welding wire is uniformly welded on the substrate, and the number of composite layers is one layer to two layers and even multiple layers. In the composite process, uniform transverse cracks occur due to different alloy shrinkage ratios. This is a prominent feature of wear-resistant steel.

The wear-resistant layer is mainly composed mainly of chrome alloys, and other alloy components such as manganese, molybdenum, niobium, and nickel are also added. The carbides in the metallographic structure are distributed in a fibrous manner, and the fiber direction is perpendicular to the surface. The carbide microhardness can reach HV1700-2000 or more, and the surface hardness can reach HRc58-62. The alloy carbide has strong stability at high temperature, maintains high hardness, and also has good anti-oxidation performance, and is fully used within 500°C.

Wear-resistant steel plate has high wear resistance and good impact performance, can be cut, bent, welded, etc., can be welded, plug-welded, bolted, etc. to connect with other structures, saving time in the process of repairing the site It is widely used in industries such as metallurgy, coal, cement, electric power, glass, mining, building materials, bricks and tiles. Compared with other materials, it has high cost performance and has been favored by more and more industries and manufacturers.

June 01, 2023

October 14, 2022

E-mail naar dit bedrijf

June 01, 2023

October 14, 2022

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.